How big of an ecological problem is food waste in Poland and worldwide?

Estimates vary but even the most cautious, optimistic calculations indicate wastage of around 40% of produced fruits and vegetables – at the production, packaging, transportation, and distribution stages. This is a massive percentage. In the European Union (where the most reliable data comes from), losses of around 88 million tons are recorded annually which means 150 billion EUR of costs. This not only affects the profitability of production but also the carbon, water, and energy footprint related to discarding such a huge amount of fruits and vegetables. The challenge we face is truly gigantic. Buying too much food that is wasted at home is just the tip of the iceberg. For instance – few of us notice the container ship arriving at the port from which a majority of the cargo might not be suitable for later consumption. If we could save just 10% of discarded fruits and vegetables, we would contribute to reducing CO2 emissions which would be equivalent to that generated by several million cars.

Our solution is based on an active substance: 1-methylcyclopropene (1-MCP). The influence of this substance was discovered over 20 years ago and since then it is been widely used in the apple production industry. Since apples need to be stored for a long period, about 10 months until the next harvest, there was a need to arrange proper conditions for the fruits. 1-MCP quickly became the standard here. It is delivered in a quite specific way – as a powder that is put into water so that it starts emitting gas in a closed refrigeration chamber. The concentration is very low (one part per million or even less), and the compound itself is safe for humans, animals, and the environment. After 24 hours, during which the apples were exposed to gas, the refrigeration chamber is ventilated and closed for almost a year. All the apples that we can buy during the winter and early summer seasons go through this process.

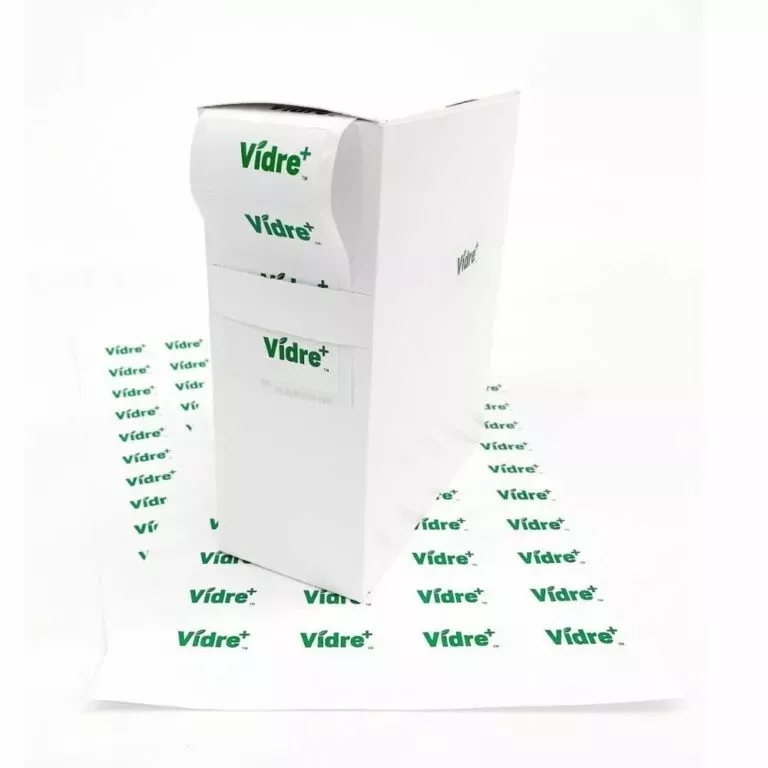

We asked ourselves why only apples benefit from this substance. We decided to find a way and an easy way to deliver 1-MCP to other fruits and vegetables. Since apples can be “secured” for up to 10 months, there had to be a way to protect them another products at all stages of the productions and delivery chain up to the store and end consumer stage. Gathering 2,000 tons of fruits and vegetables in one place was not an option. We had to work locally – in the packaging. We developed a system where 1-MCP is released directly in a clamshell-type container, box, or pallet. It took a few years from the idea to implementation. We obtained a patent based on the release of 1-MCP from our proprietary Vidre+âÂË sticker on vegetables or fruits under the influence of moisture present in them. In other words, by breathing, the vegetables and fruits generate moisture, moisture activates the sticker, and at that moment, the necessary substance is released in the package. Easy, isn’t it?

Our target market begins with producers: in the fields or orchards, and further – depending on the distribution method – we apply the sticker throughout the whole distribution chain process: at companies dealing with transportation and wholesalers. Our product is not primarily intended for the end customer. Most fruits and vegetables are wasted during transportation, and the distributor has the greatest influence on the form and quality of the products that will reach the end consumer. However, our strategy also includes consumer products. These will be packaging – for example, bags – containing 1-MCP.

At the moment, we are focused on the largest food producers’ markets. At the beginning of our journey, we focused on South America – a major producer that has to ship its products by sea and air freight – although the last one is loosing its popularity. For example, it takes 6 weeks for avocado to reach Europe, and we need to ensure that we help this produce to survive this demanding journey.

It all started in 2012. Our “parent company” – Synthex Technologies – became interested in 1-MCP. We started working on its synthesis and appropriate application form. We started by selling 1-MCP for large-scale applications. In the meantime, we were making efforts “to democratize” the 1-MCP market and provide benefits not only for apples. As chemists at Synthex Technologies, we participated in many research projects and had experience in solving various agrotechnical industry problems. The idea evolved until it found its final application in the subsidiary company, Fresh Inset.

We gained our first startup experiences as the “parent company,” Synthex Technologies. We have come a long way, during which we learned a lot. Like any brand, we went through ups and downs. However, we were very fortunate with investors. We met people who not only invest money but also provide invaluable expert support. We received tremendous help, for example, in organizing the functioning of the company. When we established Fresh Inset in 2018, the sum of these experiences worked greatly in our favor.

We are not yet a startup that earns more than it spends, but we are definitely getting closer to that point. We have already overcome the technological risks and the need to prove effectiveness and procedures. We have a ready product that is undergoing registration requirements and market approval. There are the costs associated with patent protection in 52 markets. We are already selling in Argentina, we will soon be selling in Ecuador, Peru should join this group, followed by Brazil, Colombia, and other South American countries. We are also preparing to kick off in the United States, which should definitely push us forward. Moreover our technology can also be applied to flowers. We are currently testing this in the Netherlands, Kenya and Ethiopia.

For some products, protection methods are so much in demand that we may become the market standard. I know we have such potential, and everyone will benefit from it.

The task is demanding because when our workday ends in Poland, the day is just beginning in South America. When we enter the Asian market (preparations for this are already underway, we even have a partner in India) – our day will last more than 24 hours.

However, we work with professionals. We work with our trusted people who know the specifics of the local market. We collaborate with specialists with broad expertise, in agrochemistry, tests on fruits and vegetables, plants physiology, and business development. In Latin American countries, personal relationships are crucial in business, and you need to earn trust over time. We connect almost daily, and once or twice a week, we have long team meetings to set priorities. This system works well. Surprisingly, the pandemic helped a bit with the business. Previously, it was hard to imagine running a company operating in dozens of foreign markets without constant travel and face-to-face meetings. Now everyone is used to online communication and handling serious business matters this way. I think that the world has shrunk. Standards and expectations have changed, and many things are easier now. Of course, at some point, we resumed flying; our schedule is currently packed. But we see this as a reason for joy because it is already associated with signing contracts with major players in the fruits and vegetables market.

Participating in competitions is always a great experience for us. It gives us the opportunity to get to know other brands – to see what they are doing, and what problems they are solving. Do not get me wrong, but in some way it even pleased me that we didn’t win prizes in the ING Grant Program. We are already at a more advanced stage than most startups participating in this competition. The awarded companies simply needed those grants more. I’m not surprised by the decisions of the jury. Regardless of the final outcomes, we got a chance to highlight the problem and showcase our technology. We remember this event very well – excellent organization and great atmosphere. Participation in the project and reaching the final shows that we are worthy of trust. Since the ING group has Dutch roots, we gained access to valuable contacts in the flower market.

First of all: scientists should not be afraid to collaborate with people with market experience. Every idea needs to be “built” with knowledge of commercialization. Otherwise, it will never see the daylight. This includes industrial design patent protection. Secondly: one should manage start-up financials. Thirdly: don’t be afraid to cooperate with public institutions and funds. In the vast majority of cases, such collaboration benefits startups. I often observe a strong attachment to one’s own project and some reluctance to “hand it over to someone else.” On one side, this is understandable and good, but on the other hand, it blocks growth. How are we going to convince an investor to invest if we offer them a fraction of a percent of our company’s value? A significant challenge is to properly evaluate the value – to show both the future-solving possibilities and reflect the real place where the startup is. It’s worth asking yourself what we can gain from cooperating with the right people and what we will lose if we abandon such cooperation.

On the one side, this relationship is certainly shaped by European requirements. On the other hand, I can see – especially in the food industry – that large brands are starting or are already in the process of implementing projects that go even further. Especially in reducing the carbon footprint in the transportation sector. There are many great and useful programs. This shows that the ecological aspect of business is becoming really important and attracts customers. A lot of interesting things are also happening in the chemical and agrochemical sectors. It’s not something you see every day because it’s deeply ingrained in technology, but work on increasing product safety and process improvement is ongoing. Ecology can be observed at many different levels. We still have a long way to go, but we are heading in the right direction.

Thank you.