The floral industry faces a challenge with the detrimental impact of ethylene gas on flowers, particularly roses, which leads to premature petal drop, bud decay, and reduced bloom quality. This issue not only affects the aesthetic and commercial value of flowers but also contributes to significant waste, exacerbating the environmental footprint. In response to this challenge, Fresh Inset has developed Vidre+™ an innovative technological solution. By targeting the negative effects of ethylene gas, Vidre+™ significantly extends the lifespan of sensitive species like roses, effectively reducing waste and addressing environmental concerns. The trials showcasing Vidre+™’s ability to enhance the longevity of roses affirm its potential as a key solution to sustain the industry’s vibrancy and mitigate ecological impacts.

Flowerwatch conducted an efficacy test of 1-MCP stickers (Vidre+™) on cut roses, comparing them with STS-treated and untreated control roses. Four varieties of ethylene-sensitive roses were tested in each treatment, with four vases for each.

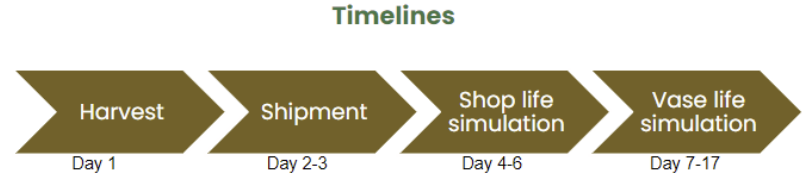

The research journey began from the harvest stage, where roses were carefully picked and prepared into bunches. At this foundational step, Vidre+™ stickers were applied to the cardboard packaging, and the boxes were subsequently palletized on air pallets, ready for their next journey.

In the shipment stage, transport usually takes from 1 to a maximum of 2 days. This phase included vacuum cooling of the flowers before they were air freighted. Upon arrival, the boxes were collected from the importer and unpacked, marking the transition into post-shipment handling. Here, the roses received a fresh cut and were placed in buckets with water, and stored in a cold room for a day to recuperate from their travels.

The next phase, shop life simulation, closely mimicked the conditions the roses would face in a retail environment, set at 20°C, with 1000 lux lighting, and alternating 12 hours of dark and light to simulate day and night.

The conclusion of the research was the vase life simulation, which served as the final testing phase. It included a detailed examination of the vase life of flowers on the 7th day after harvest, and additionally, the studies were extended to include checks on the 10th-day post-harvest. During this time, the roses were meticulously monitored under conditions of relative humidity of ± 50 – 70% and an average temperature of ± 20°C, alongside an established 12-hour dark/light cycle. This comprehensive approach provided valuable insights into the endurance and visual appeal of the roses throughout their post-harvest life.

photo: On day 7 of the vase life test, the roses were judged on the total vase life.

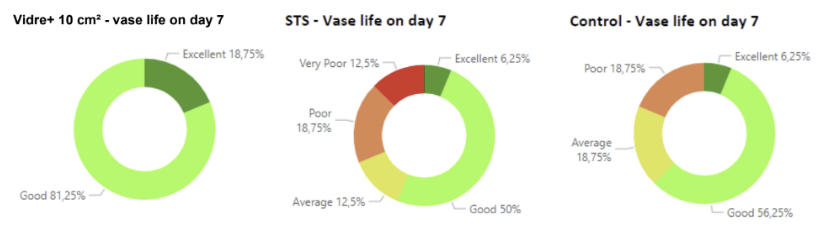

The vase life simulation study focused on air-freighted cut roses and their total vase life, as well as their susceptibility to bud withering. The study evaluated the performance across four varieties of ethylene-sensitive roses.

Initial findings, reported on the seventh day of the vase life test, revealed that 18.75% of the untreated roses were classified as in poor condition, with an identical percentage marked as average. Conversely, a significant majority, 56.25%, were deemed to be in good condition, while 6.25% achieved an excellent rating. In contrast, roses treated with Vidre+™, incorporating the active ingredient 1-MCP at 4 ppm, exhibited notably superior results; 81.25% were in good condition and 18.75% were rated as excellent, with no instances of poor or average conditions observed after one week, attributing to the efficacy of Vidre+™.

photo: Roses vase life simulation

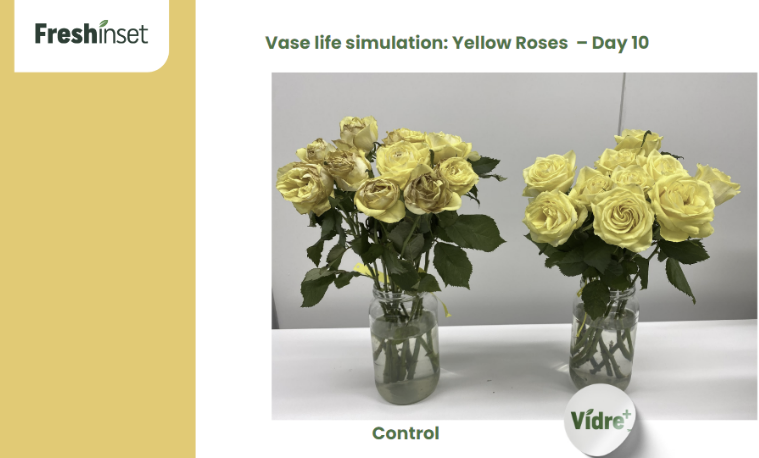

Further testing on specific rose varieties reinforced the initial findings, with the most remarkable outcomes observed after 10 days of vase life simulation.

In the case of red roses, all flowers in the untreated control group were classified as very poor. However, after treatment with Vidre+™, 50% of the roses were in average condition.

Yellow roses showed even more impressive results. After 10 days, the majority of the untreated control group was in poor (50%) or very poor (25%) condition, whereas 50% of the roses treated with Vidre+™ were in excellent condition.

photo: Yellow Roses vase life simulation (day 10)

Research indicates that Vidre+™ technology more effectively extends the vase life of cut roses than STS treatment in the same study. These findings highlight Vidre+™ potential to reduce waste and contribute to the sustainability of the floral industry by mitigating the effects of ethylene sensitivity.

Roses receiving the Vidre+™ treatment display:

This outcome is particularly beneficial for commercial cultivators and retailers seeking to guarantee that their flowers are delivered to the market in peak condition, thereby maintaining their aesthetic appeal over a longer duration. Consequently, this approach contributes to minimizing financial losses associated with unsold or deteriorated flowers with an anti-ethylene treatment like Vidre+™, roses become less or not sensitive to ethylene damage, making it easier for them to reach the 7-day vase life guarantee offered by most European retailers.

*Source: Research report: 50000837-538-02 conducted by Flower Watch, Date: February 2023