Tomatoes are one of the most popular fresh produce crops among consumers worldwide. For example, in the U.S. market tomatoes were the second-most purchased vegetable in 2021, according to The Packer’s Fresh Trends 2022. When choosing fresh tomatoes at the store, consumers look for bright, shiny, red skins and firm flesh. So how to ensure that consumers receive top-quality tomatoes and minimize food waste across the tomato supply chain at the same time? Vidre+ is an answer.

Tomatoes are a climacteric crop. This means that they experience an increase in respiration and ethylene production at the beginning of the ripening process. In general, ethylene affects the quality of all fruit and vegetables after harvest, which finally results in reduced shelf-life and quality over time. In the case of tomatoes, ethylene is essential to begin tomato ripening. However, once tomatoes begin turning color, ethylene leads to tomato senescence and softening. But there is a solution to this challenge – by using Vidre+ the ripening process of tomatoes can be slowed down and as a result, the following can be obtained:

The trials conducted in Argentina show significant results on tomatoes due to the application of Vidre+ in the form of stickers. The test consisted of tomato color evaluation, based on the commonly used standard tomato ripening color scale.

Freshly harvested tomatoes were placed in wooden crates following standard commercial practice, each holding 18kg of tomatoes. Each crate was wrapped in plastic bags for 30 hours and then they were removed. Researchers followed standard commercial practices and made daily observations on color evolution. After 7 days, the untreated tomatoes turned red, while the ones treated with Vidre+ remained in stage 3, which means that more than 10% but less than 30% of the surface of tomatoes show a change from green to yellow or pink red. Vidre+ tomatoes reached optimum eating quality between days 12-18. This slow-down in ripening can be an excellent tool for producers to selectively manage inventory at times of peak harvest, thereby reducing waste.

Day 7 of the test. Untreated tomatoes turned red (stage 6), while Vidre+ ones ripened more slowly and reached optimal eating quality on Day 12.

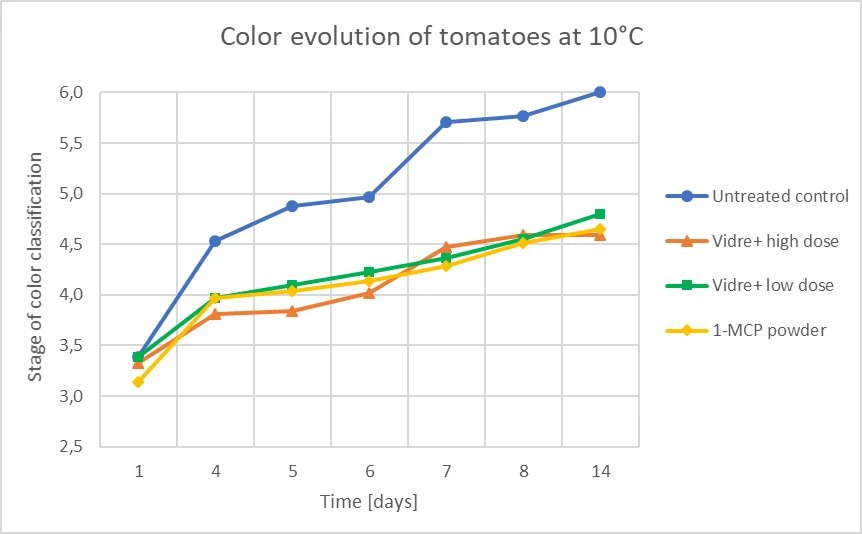

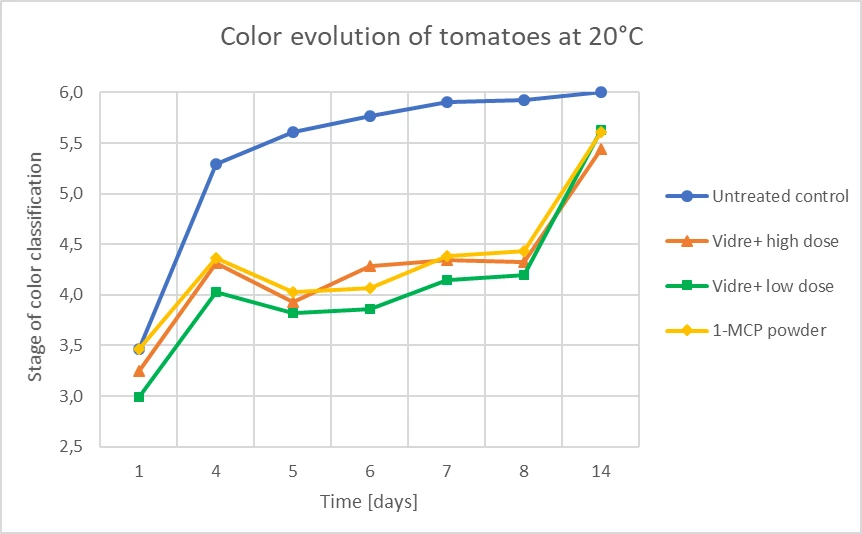

Another test conducted with Vidre+ was performed on the commercial packaging, that is 500g clamshell packaging. High-dose and low-dose Vidre+ stickers were pasted into clamshells filled with tomatoes. The use of 1-MCP powder and untreated control were also studied. The experiment was carried out for 14 days, which is a standard storage length. The results precisely show the efficacy of Vidre+ is delaying the color evolution of tomatoes at both temperatures – 10 and 20 celsius degrees.

|

|

Color evolution of tomatoes at 20 and 10 Celsius degrees

To present the difference in the color evolution of tomatoes with Vidre+ protection vs. untreated ones, we have prepared a time-lapse animation. We documented the appearance of Vidre+ protected tomatoes vs. control ones for over 20 days until the untreated tomato lost their commercial quality. The one supported by Vidre+ was still in good condition.

See the difference for yourself!

If you have any questions about our Vidre+ solution, please do not hesitate to contact us by email krzysztof.czaplicki@freshinset.com.